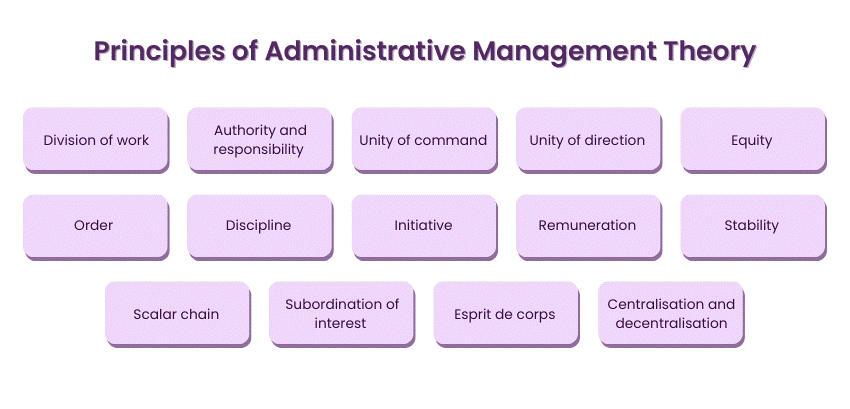

Henry Fayol’s 14 Principles of Management:

Fayol’s 14 Principles of Management provide a guide for managing an organization efficiently, especially in the context of operations. These principles can help organizations structure their operations, allocate resources effectively, and manage human resources in a way that improves productivity.

-

Division of Work

- Dividing tasks into smaller, specialized roles increases efficiency and expertise. Specialization is a cornerstone of operations management, as it enhances productivity and reduces errors.

- Example: In a manufacturing plant, workers might be assigned specific tasks like assembly, inspection, or packaging, leading to greater efficiency and quality.

-

Authority and Responsibility

- Managers must have the authority to give orders and the responsibility to ensure tasks are performed. In operations, this principle ensures that the right people are held accountable for completing the tasks effectively.

- Example: A production manager is given the authority to manage the assembly line and is responsible for meeting production targets.

-

Discipline

- Employees must follow organizational rules and agreements. In operations, discipline is vital for ensuring safety standards, following work procedures, and maintaining quality control.

- Example: Workers in a factory must adhere to safety protocols and the standard operating procedures (SOPs) to avoid accidents and maintain smooth operations.

-

Unity of Command

- Each employee should report to only one superior to avoid confusion and conflicting instructions. In operations management, this ensures clear decision-making and accountability.

- Example: An employee working on the production floor should only report to one supervisor to avoid conflicting instructions from multiple managers.

-

Unity of Direction

- The Unity of Direction principle states that activities with the same objective should be organized under one plan and one head.

This ensures coordinated effort and avoids duplication or conflict.

It is key for aligning departmental efforts toward organizational goals. - Example: In a company, all departments such as production, quality control, and logistics should align their efforts to ensure timely delivery of high-quality products.

- The Unity of Direction principle states that activities with the same objective should be organized under one plan and one head.

-

Subordination of Individual Interest to General Interest

- The interests of the organization should take priority over individual interests. In operations, this helps align individual efforts with the organization’s overall goals.

- Example: A worker may prefer to finish one task quickly, but the overall production schedule requires collaboration and pace coordination across teams.

-

Remuneration of Personnel

- Employees should be fairly compensated for their contributions. In operations, providing competitive wages and benefits is essential for retaining talent and motivating employees.

- Example: A fair payment system in a manufacturing unit can motivate employees to meet production targets and stay loyal to the company.

-

Centralization vs. Decentralization

- The balance between centralized decision-making (top-down) and decentralized decision-making (spread out across various levels). In operations, the right balance is crucial for decision-making efficiency and responsiveness.

- Example: A company might centralize financial decisions but decentralize production decisions to allow factory managers more flexibility in managing operations.

-

Scalar Chain (Chain of Command)

- A clear chain of authority within the organization should exist. In operations, this ensures that tasks are performed in a systematic and structured manner, with clear reporting lines.

- Example: A factory worker reports to a supervisor, who in turn reports to the production manager, ensuring smooth communication and accountability.

- Order

-

- Both human resources and physical resources should be properly organized. In operations, maintaining order leads to efficiency, less waste, and improved workflows.

- Example: Organizing raw materials, tools, and workstations in a factory so they are easily accessible leads to smoother production processes.

- Equity

-

- Employees should be treated fairly and with respect. In operations, fairness helps maintain morale and a positive working environment, leading to higher productivity.

- Example: Treating workers fairly when assigning tasks or rewarding performance can lead to higher employee engagement and fewer disputes.

- Stability of Tenure of Personnel

-

- Organizations should aim to reduce turnover and retain experienced employees. In operations, a stable workforce improves efficiency and reduces the costs of training and recruiting new employees.

- Example: A factory that maintains a stable team of workers over time is likely to see improved productivity due to the employees’ experience and familiarity with the work.

- Initiative

-

- Employees should be encouraged to take initiative and contribute ideas. In operations, encouraging initiative helps foster innovation and continuous improvement.

- Example: Encouraging workers to suggest improvements to the production process can lead to innovative solutions and better efficiency.

- Esprit de Corps (Team Spirit)

-

- Promoting harmony and teamwork within the organization is essential. In operations, a sense of unity and collaboration leads to a more motivated and effective workforce.

- Example: Creating a team-oriented environment where production workers cooperate with maintenance and logistics teams ensures a smoother workflow and better results.

Henry Fayol’s 14 Principles of Management, proposed in 1916, form the foundation of many modern management practices, including operations management.