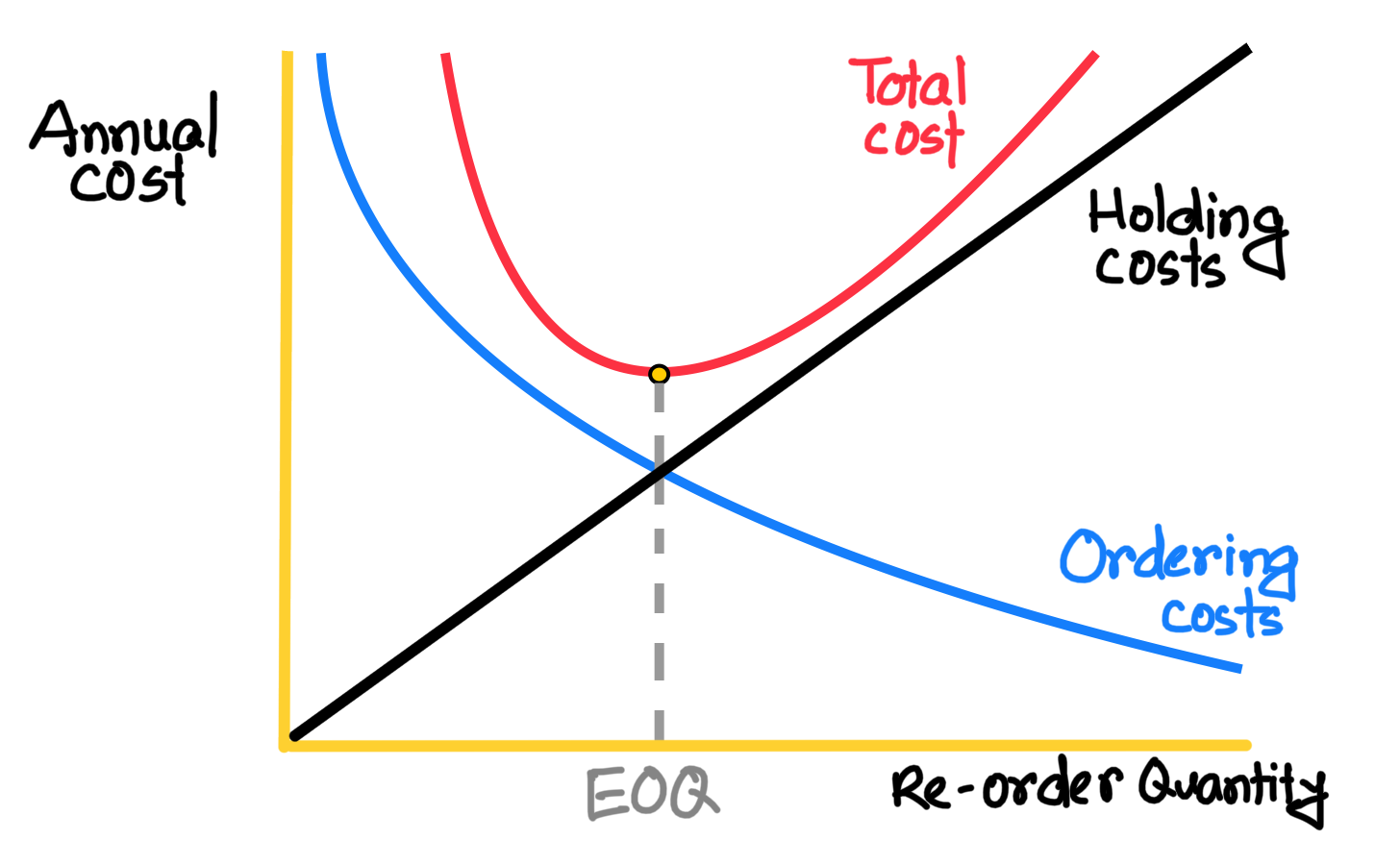

EOQ (Economic Order Quantity) is a key concept in inventory management, used to determine the optimal order quantity that minimizes the total cost of inventory. The goal of EOQ is to balance the costs of ordering inventory and holding inventory to find the most cost-effective order size.

Assumptions:

- The demand for the product is constant and known.

- Ordering costs and holding costs are fixed.

- Lead time (the time it takes to receive an order) is constant.

- There are no quantity discounts.

Key Components of EOQ:

- Demand (D): The number of units of a product required per period (usually per year).

- Ordering Cost (S): The cost associated with placing and receiving an order. This includes administrative costs, transportation, and delivery charges.

- Holding Cost (H): The cost of storing unsold inventory. It includes storage, insurance, and opportunity costs of capital tied up in inventory.

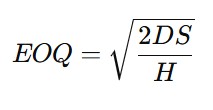

EOQ Formula:

The EOQ formula is given by:

Where:

- EOQ = Q = Order Quantity

- D = Demand (units per period)

- S = Ordering cost per order

- H = Holding cost per unit per period

How EOQ Works:

- Ordering Costs: When you order more units at once, the number of orders per year decreases, reducing the ordering costs. However, larger orders mean you need more space to store inventory, leading to higher holding costs.

- Holding Costs: If you order fewer units, you have more frequent orders, increasing ordering costs, but reducing the amount of inventory you need to store, lowering holding costs.

The EOQ model aims to find the balance between these two opposing costs (ordering and holding) to minimize total inventory costs.

Total Cost Formula:

The total cost of inventory is the sum of ordering costs and holding costs, and is given by:

Where:

- Ordering Costs = [D/Q] × S

- Holding Costs = [Q/2] × H

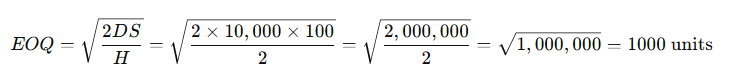

Example 1:

Let’s say a company sells 10,000 units of a product per year (D = 10,000), the ordering cost per order is $100 (S = 100), and the holding cost per unit per year is $2 (H = 2).

Using the EOQ formula:

So, the company should order 1,000 units at a time to minimize the total inventory costs.

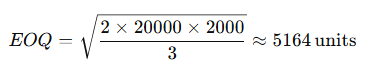

Example 2:

What should be the economic order quantity (EOQ) for procurement of 20000 units annually at a price of ₹ 12 per unit for consumption in production, when the cost per order is ₹ 2000 and the inventory carrying cost is 25 % percent of Inventory value?

Inventory carrying cost = 25% of unit cost = 25% × ₹12 = ₹3 per unit per year

Benefits of EOQ:

- Cost Minimization: EOQ helps reduce the total cost of inventory by finding the ideal order size.

- Efficient Inventory Management: It helps maintain the right balance between inventory levels and ordering frequency.

- Improved Cash Flow: By minimizing excess inventory, companies can free up capital for other uses.

Conclusion:

EOQ is a critical tool for inventory management that helps businesses determine the optimal order quantity to minimize total costs. By balancing the ordering and holding costs, businesses can improve their operational efficiency and reduce unnecessary expenses.