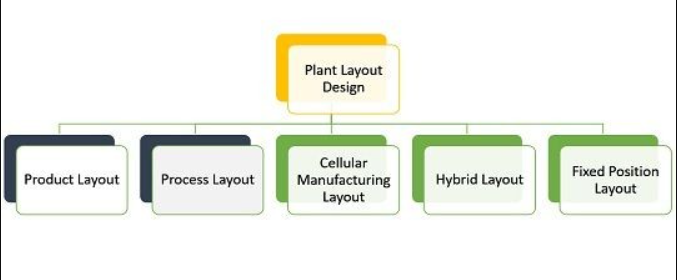

Plant layout design refers to the arrangement of machinery, equipment, workstations, and other resources within a manufacturing facility.

It plays a crucial role in maximizing the efficiency, safety, and productivity of a plant by minimizing unnecessary movement of materials, workers, and equipment.

There are several types of plant layouts, each suited to different types of production processes.

The choice of layout depends on factors like the volume of production, type of product, machinery requirements, and operational efficiency.

1. Process Layout (Functional Layout)

-

Description: In a process layout, similar machines or equipment are grouped together by function. For example, all drilling machines are located in one section, all assembly machines in another, etc.

-

Best for: Job shops or custom production with a variety of products.

-

Advantages:

-

Flexible for varying production requirements.

-

Ideal for low-volume, high-variety production.

-

-

Disadvantages:

-

More complex material handling and transportation.

-

Longer lead times due to distance between related machines.

-

Example: A factory that makes custom parts where the production process involves many different stages.

2. Product Layout (Line Flow Layout)

-

Description: In a product layout, equipment and workstations are arranged in a linear sequence based on the product’s production flow. Each station performs a specific task along the assembly line.

-

Best for: Mass production of standardized products with high production volumes.

-

Advantages:

-

Simplifies material handling (since products move along a set path).

-

Reduces lead time and increases efficiency.

-

Lower labor costs due to standardized tasks.

-

-

Disadvantages:

-

Less flexible, not ideal for varying production needs.

-

High initial setup cost.

-

Downtime in one station can halt the entire line.

-

Example: Automobile assembly line where each station performs a specific task like attaching wheels, engines, etc.

3. Cellular Layout (Cell Layout)

-

Description: This layout organizes the plant into cells, each containing all the equipment needed to produce a family of similar products. The machines in each cell are arranged in a way that minimizes material handling.

-

Best for: Flexible manufacturing systems or batch production where products can be grouped into families with similar processes.

-

Advantages:

-

Reduced transportation time.

-

Flexible for small to medium-volume production.

-

Improves team coordination.

-

-

Disadvantages:

-

Requires balancing and careful grouping of products.

-

Higher equipment costs due to multiple machines in each cell.

-

Example: A factory that produces different models of smartphones, where each cell focuses on assembling specific components of those models.

4. Fixed Position Layout

-

Description: In this layout, the product remains stationary in one location, and workers, materials, and equipment come to it. It is typically used for large, bulky, or complex products that cannot be easily moved.

-

Best for: Large-scale projects like shipbuilding, airplane assembly, or construction.

-

Advantages:

-

Ideal for manufacturing large, heavy, or complex products.

-

More flexibility in terms of product design and production.

-

-

Disadvantages:

-

Inefficient use of space and materials.

-

High labor costs due to movement of workers and equipment.

-

Coordination and scheduling challenges.

-

Example: Shipbuilding, where the ship remains in one place while workers and materials come to the site.

5. Combination Layout / Hybrid Layout

-

Description: This is a hybrid layout that combines elements of both product and process layouts. It is designed to suit complex manufacturing needs that cannot be efficiently handled by a single layout.

-

Best for: Manufacturers that produce a range of products in varying quantities.

-

Advantages:

-

Provides flexibility for various product types.

-

Suitable for manufacturers with mixed-volume and mixed-product production.

-

-

Disadvantages:

-

May be complicated to manage.

-

Not as streamlined as a pure product or process layout.

-

Example: A factory that manufactures both mass-produced and custom-designed products.