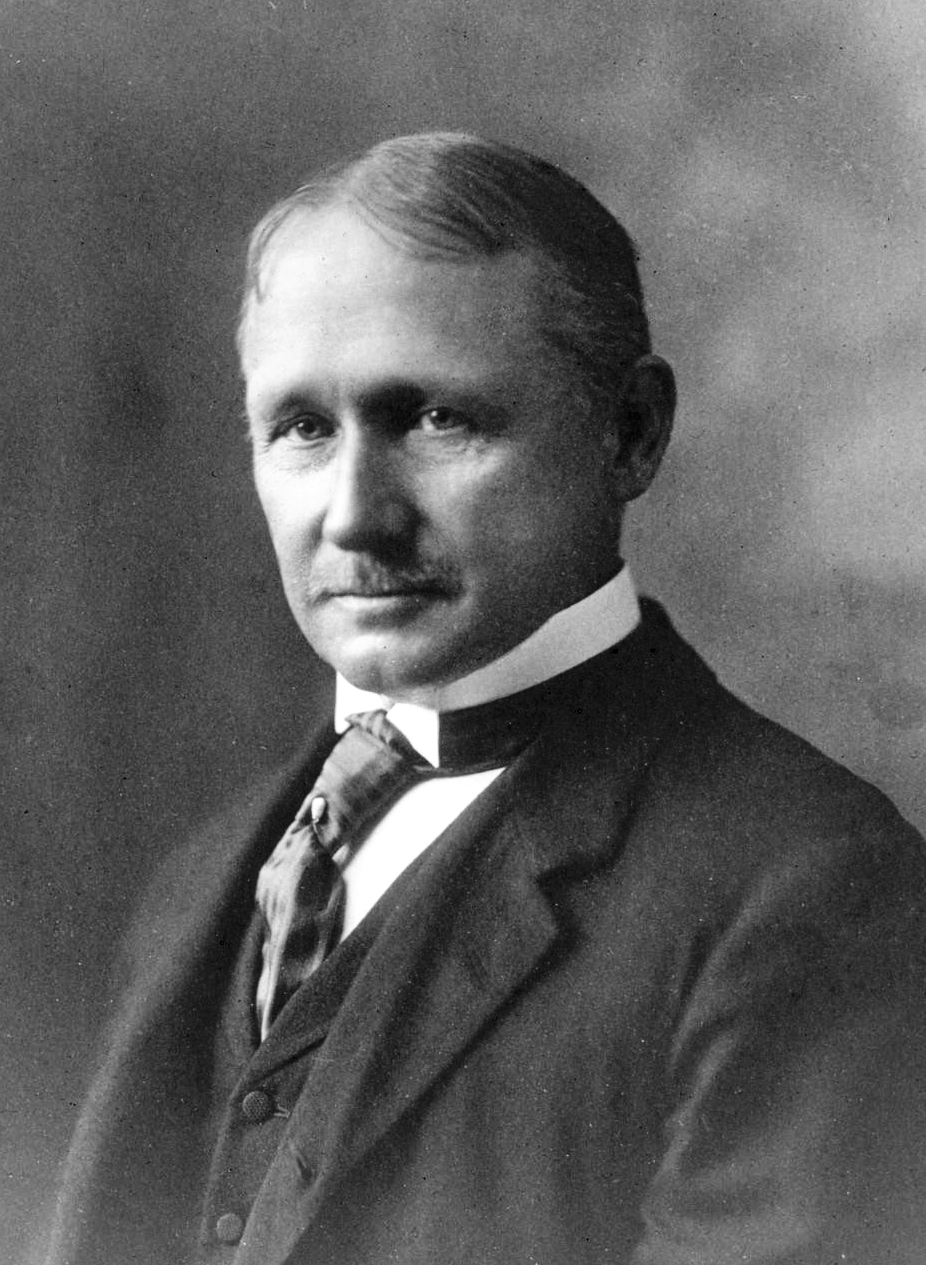

Scientific management is a theory of management that analyses and synthesizes workflows. Its main objective is improving economic efficiency, especially labour productivity. It was one of the earliest attempts to apply the science of engineering processes to management. Scientific Management is also known as Taylorism after its pioneer, Frederick Winslow Taylor.

Taylor began the theory’s development in the United States during the 1880s and 1890s within manufacturing industries, especially steel. Its peak of influence came in the 1910s. Although Taylor died in 1915, by the 1920s scientific management was still influential but had entered into competition and syncretism with opposing or complementary ideas.

Although scientific management as a distinct theory or school of thought was obsolete by the 1930s, most of its themes are still important parts of industrial engineering and management today.

Techniques Introduced by Taylor:

-

Time Study: Measuring time taken for tasks to set performance standards.

-

Motion Study: Analysing physical movements to eliminate wasteful actions.

-

Standardization: Creating uniform procedures, tools, and conditions.

-

Piece-Rate System: Paying workers based on output to motivate higher productivity.

Criticisms of Scientific Management:

| Critique | Description |

|---|---|

| 🤖 Dehumanization of Workers | Treats workers as mere tools for productivity, neglecting their human needs, leading to alienation. |

| 🔄 Over-Simplification and Repetitiveness | Jobs become monotonous and repetitive, reducing worker satisfaction and creativity. |

| 😓 High Pressure on Workers | The focus on maximizing output creates stress and pressure on workers to perform, often leading to burnout. |

| ⚙️ Narrow Focus on Efficiency | Emphasis on efficiency ignores worker well-being, motivation, and other factors that contribute to long-term success. |

| ✊ Resistance from Workers and Unions | Workers and unions resist Scientific Management due to its restrictive nature and control over workers. |

| 🧠 Limited Applicability to Complex Jobs | Not effective for complex, creative tasks that require flexibility and problem-solving, as it focuses on routine. |

| 📊 Over-Reliance on Quantification | Excessive focus on quantitative measurements (e.g., time studies) can overlook qualitative factors like job satisfaction. |

Relevance Today:

Though developed over a century ago, Taylor’s principles laid the foundation for modern operations management, lean manufacturing, and performance optimization.